Brands need the ability to manage and optimize their supply chain intelligently as we enter an era of intelligent orchestration. They can partly address intelligent orchestration by utilizing a Cloud Supply Chain approach to managing inventory — from freight to warehousing to fulfillment — but that’s only half of the battle.

To truly optimize supply chains, we also need to be smart about what happens inside the “four walls” of the warehouse.

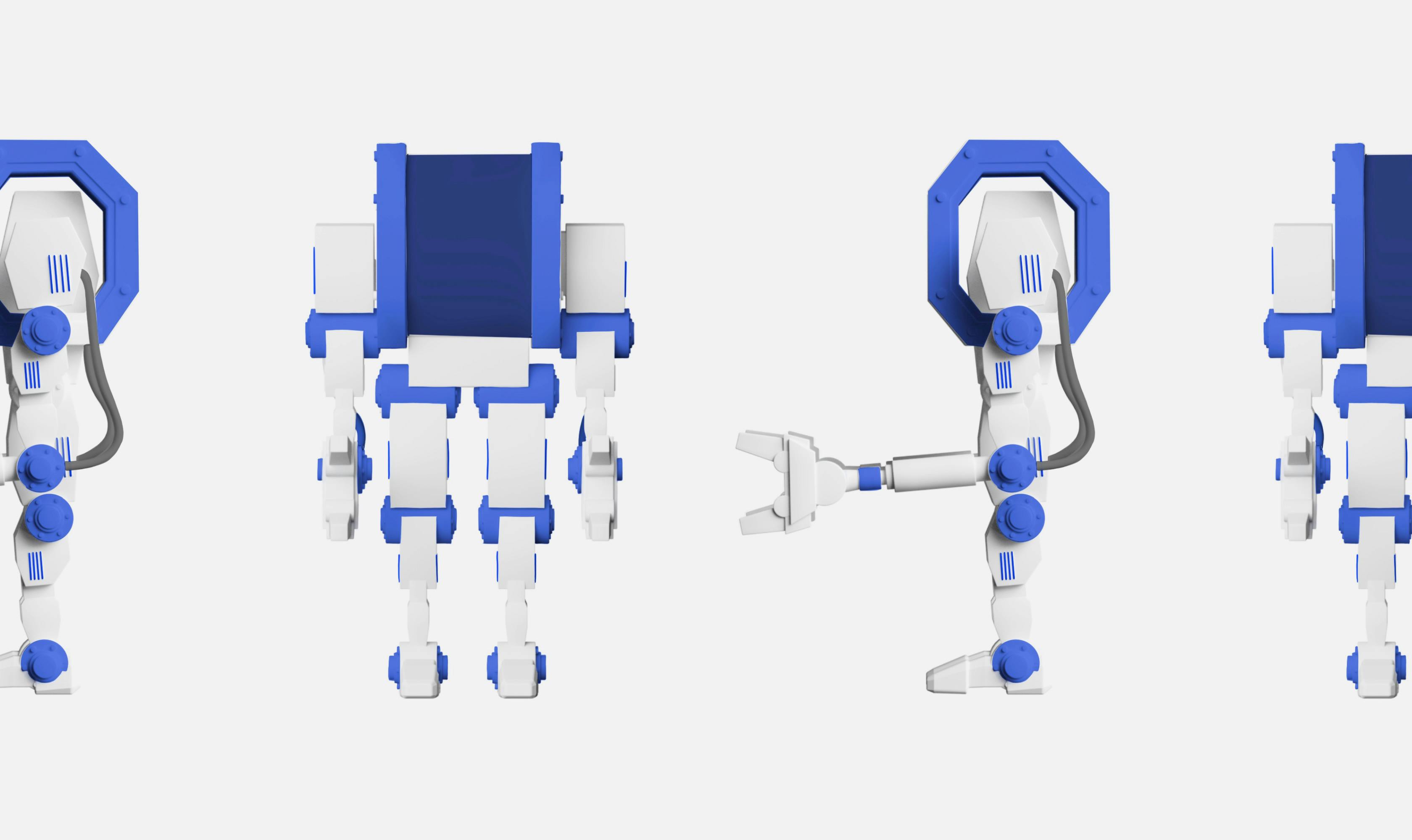

Technological developments, such as autonomous mobile robots (AMRs), are creating new ways to leverage human capital with automatic processes and allow workers to focus mainly on value-added activities.

Why the Supply Chain Is a Mess

The pandemic period pushed a large majority of the world inside. As a result, e-commerce has increased exponentially over the last two years, with statistics showing a 50% e-commerce increase from 2019.

However, 80% of the operating distribution centers (DCs) across the U.S. are manually operated, which means they need people to run them. The supply of warehouse workers has not increased with e-commerce demand – research places warehouse worker demand at a ratio of 6 to 1. That’s six positions for every single available worker.

To further exacerbate the shortfall, DC employee turnover rates are high, averaging 36% per year. High turnover means DCs lose what they’ve invested in on-the-job training and the considerable familiarity workers had developed with the centers over time. In addition, without long-term employees, overall efficiency decreases, resulting in higher costs for distribution center providers.

AMRs for the Mundane, People for the Skilled

DCs can resolve both e-commerce and high-turnover issues by leveraging AMRs. Also referred to as collaborative robots (or “cobots”), the robots can take over non-value-added tasks so workers can focus on what they’re better at – tasks that require human intelligence, dexterity, and decision making.

Efficiently Managing Non-value-added Tasks

AMRs can handle many repetitive, monotonous, and injury-prone warehouse tasks more efficiently and effectively than humans, while humans can handle the tasks that require brain functions and continue to perform those tasks manually.

Walking time is the number one non-value-added task in the warehouse. Not only does it eat up time, it leads to injuries from carrying items and other issues. It’s far more efficient for AMRs to move items from one place to another.

While some AMRs are able to pick and see, they are cost-prohibitive and limited in what they can currently do. As technology improves, robots will be able to take on more menial tasks and become more cost-effective.

When Exactly Will Robots Take Over our Warehouses?

We’re not there yet. Though many reports and publications would have you believe that autonomous robots will be in every warehouse within the next couple of years, that won’t happen with around 80% of DCs still being manually operated. Even Amazon, objectively the largest player in the e-commerce world, has been implementing robotic systems for years but is still nowhere near being fully automated.

This isn’t because DCs don’t want to automate – they do. Rather, today’s robotic systems are not “one size fits all” and each automation system has particular use cases required to generate the necessary ROI. Each DC needs to study both its existing and future customer profiles to choose the right solution. In addition, properly implementing robotics requires dedicated resources and organizational alignment, which can be challenging to achieve.

The key is to understand your customers, your current throughputs, your objectives, and study the logistics robotics space, because it’s moving very quickly. You also need to understand the capabilities of each provider’s automation system — and more importantly, each system’s limitations. The key is to choose wisely but remain flexible to achieve ultimate success.

Intelligent Orchestration to Unf**k the Supply Chain

Stord has partnered with Locus Robotics to use its AMRs to recognize over 50% efficiency gains in our flagship DC. Yet, we continue closely monitoring how market demands will impact the future production of robotic systems. By leveraging robotic systems, we maximize our fulfillment capabilities by combining both automation and our warehouse workers, even during staffing challenges facing the industry.

Based on the potential for AMRs and what we’ve seen in our own DC, we believe autonomous robots are critical to moving into the next phase of efficient warehouse operations and combating supply chain issues. They enable companies to focus on the safety of employees and expedite the logistics process, increasing capacity and reducing costs.

AMRs can help brands manage and optimize their supply chain intelligently in the era of intelligent orchestration.

As we like to say at Stord, we are “unf**king the supply chain.”